Underground – Idlers

Tapered Roller Bearing

Link-Belt® tapered bearing idler rolls are perfectly suited for continuous material handling operations moving massive volumes of tough, abrasive materials such as coal, iron ore, and rock products. Boasting load ratings that exceed CEMA requirements, this rugged line is available in CEMA D, E, and F series models. Each roller is equipped with a solid carbon steel shaft for minimum deflection under load, resulting in increased service life.

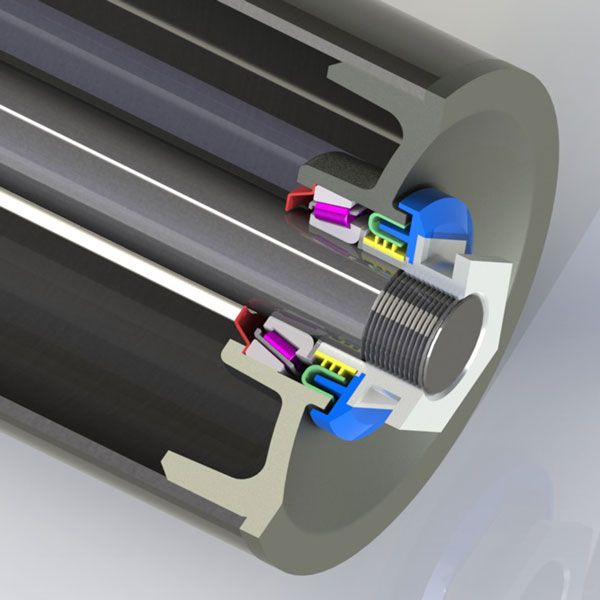

Advanced Sealing System

Link-Belt sealed for life tapered roller bearing idlers feature factory-lubricated and sealed for life rolls which eliminates re-lubrication maintenance costs. They feature a triple lip rubber contact seal paired with a nylon deflector nut and integrated labyrinth seal that protects the precision tapered roller bearings in several ways. The outer deflector nut features a 90° contoured lip to deflect material away from the roll end. The triple lip contact seal and grease-filled labyrinth ensure against the ingress of performance-inhibiting contaminants.

Maximum Corrosion Protection

Link-Belt rolls are protected from corrosion by a polymeric powder coating baked on at high temperatures to provide resistance to abrasive elements. Outer adjusting nuts and assembly hardware are zinc-plated to minimize corrosion and ensure extended service.

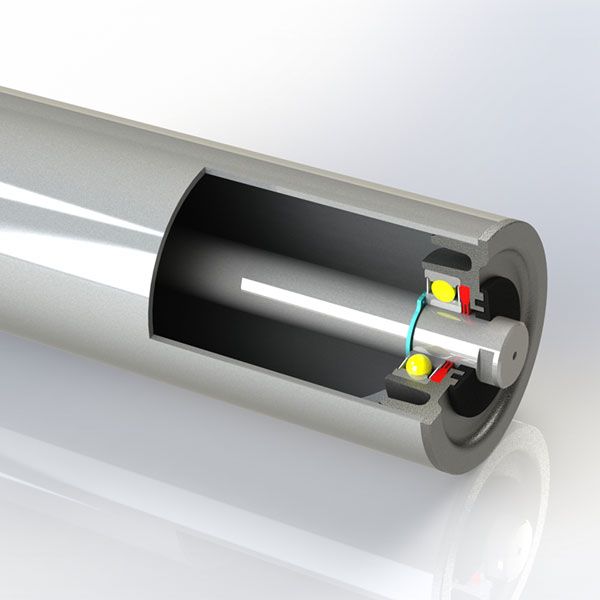

Ball Bearing

Link-Belt belt conveyor idlers and components set the standard of excellence for bulk material handling throughout the world. We offer a full line of ball bearing idler products that meet or exceed CEMA D and E specifications. Our ball bearing idlers feature advanced bearing technology for less rolling resistance than competing designs. Efficient bearing placement minimizes shaft deflection and extends bearing life. Moreover, the bearings are sealed for life, resulting in maintenance-free service. The new bearing technology also helps to ensure quality control in the manufacturing process and to extend roll life.

Link-Belt ball bearing idlers are radically different from competitive belt conveyor idlers because they incorporate an interference-fit pressed head design to maintain roll integrity. This head design eliminates welding and any of its associated problems (such as distortion, misalignment, or poor weld quality) and delivers very low total indicator runout (TIR) values compared to welded roll designs. Pressed heads, optimum bearing placement, accurate bearing alignment, and solid carbon steel shafting enable Link-Belt idler rolls to exceed CEMA load ratings.