Tapered Roller Bearing Idlers

Link-Belt® tapered bearing idler rolls are perfectly suited for continuous material handling operations moving massive volumes of tough, abrasive materials such as coal, iron ore, and rock products. Boasting load ratings that exceed CEMA requirements, this rugged line is available in CEMA D, E, and F series models. Each roller is equipped with a solid carbon steel shaft for minimum deflection under load, resulting in increased service life.

Link-Belt® D3000 series idler

The Link-Belt D3000 series idler is manufactured to CEMA dimensional standards and exceeds CEMA D idler load ratings. The C/D3000 idler features factory lubricated and sealed-for-life rolls, which eliminate re-lubrication maintenance costs. The C3000 line is also available with lubrication fittings at both ends of the idler for ease in field re-greasing from either side of the conveyor. This series features a full line of idler types for every application. The D3000 is available in 24”-72” belt widths, features a labyrinth and triple lip seal, and uses precision tapered roller bearings.

Link-Belt® E4000 Series Idler

The Link-Belt E4000 series idler line features factory lubricated and sealed-for-life rolls, which eliminate re-lubrication maintenance costs. The E4000 Idler line is also available with lubrication fittings at both ends of the idler for ease in field re-greasing from either side of the conveyor. Boasting load ratings exceeding CEMA E requirements, this idler line is designed for maximum capacity and continuous handling of most abrasive materials.

The design of the E4000 rollers, available in 36"-96" belt width 20, 35, and 45 degree troughed, positive action training, impact, and return idlers, extended, trouble free service life for your belt conveyor equipment. The series E4000 rollers, available in both 6" and 7" diameters, feature an exclusive, full length center tube and precision die-formed heads that are recessed into hot rolled mechanical shells. The entire unit is then continuously welded robotically, thus ensuring an integral, airtight unit wherein contaminants and corrosion cannot enter. This unrivaled center tube design guarantees perfect shaft/bearing alignment. Using solid, cold drawn steel shafts to minimize deflection and increase load ratings increases bearing life.

Series E4000HD heavy-duty idler assemblies are recommended where loads exceed CEMA E ratings. The heavy-duty stepped shaft design with standard 1-1/4" bearings will, in many cases, permit the conveying of loads up to 50% greater than the normal capacities. Available in 6" and 7" diameter rolls, the carrying idler’s external dimensions are identical to Series E4000. All series E4000HD heavy-duty idlers are available for belt widths up to 72".

Link-Belt® F5000 idler

Syntron Material Handling and CEMA recognize that many new material handling conveyor systems are being designed and fabricated throughout the world requiring substantially greater tonnage capabilities, exceeding 10,000 MTH in certain instances. We are in the forefront of this effort to lead the way as the first idler manufacturer in the world to offer the F series line. The Link-Belt® series F5000 belt conveyor idler line, boasts load ratings up to 80% greater than CEMA E idlers to handle the most extreme material capacities and lump sizes.

Our top of the line Link-Belt series F5000 idler portfolio features rugged 20, 35, and 45 degree troughed and return idlers supplied with 7" or oversized 8" diameter rollers in belt widths ranging from 48" - 120".

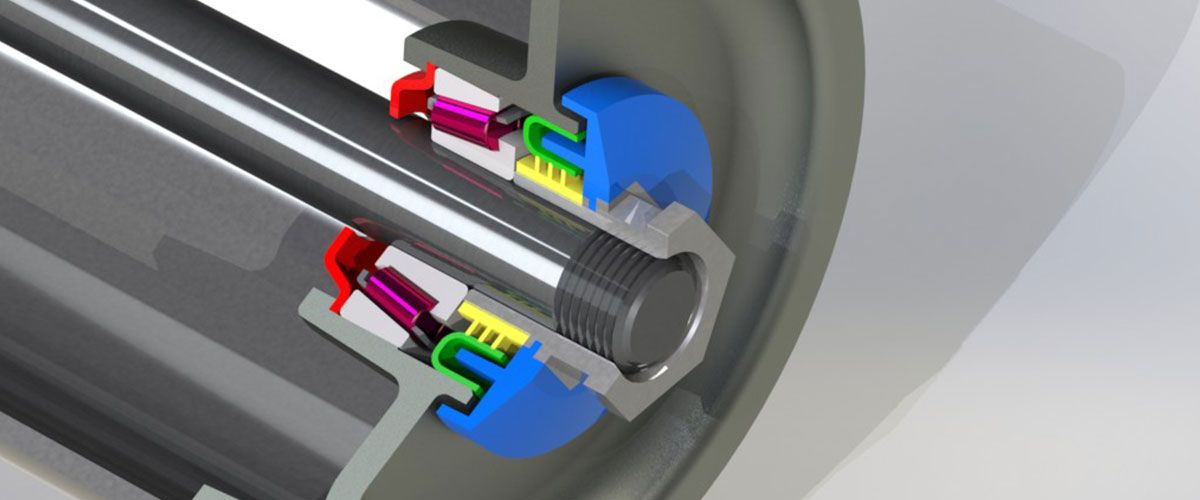

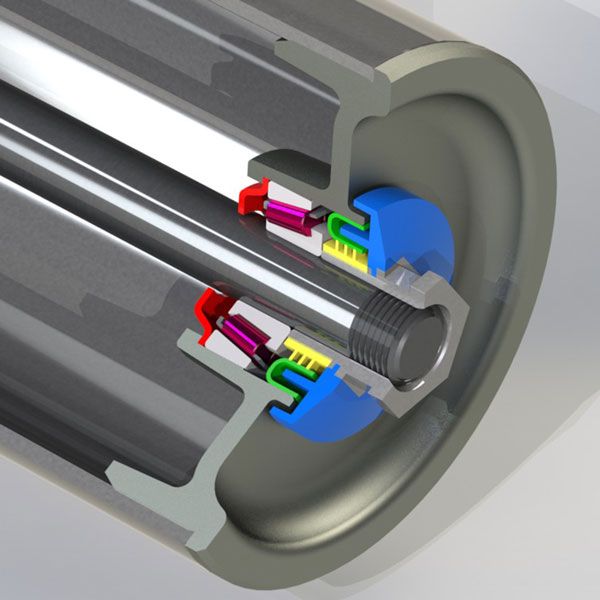

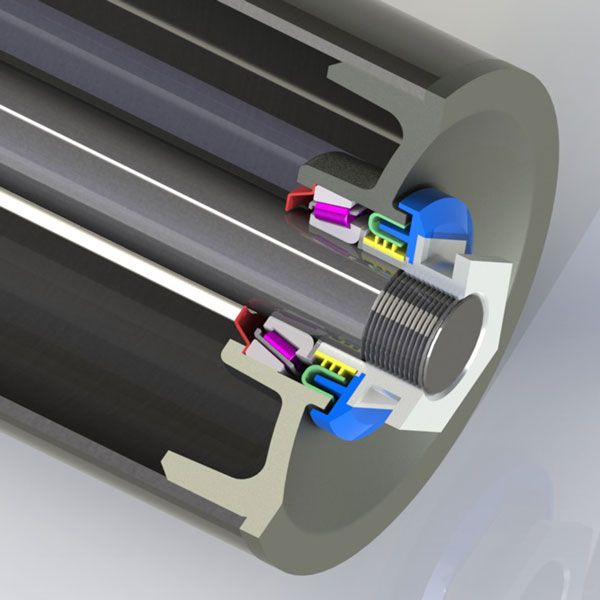

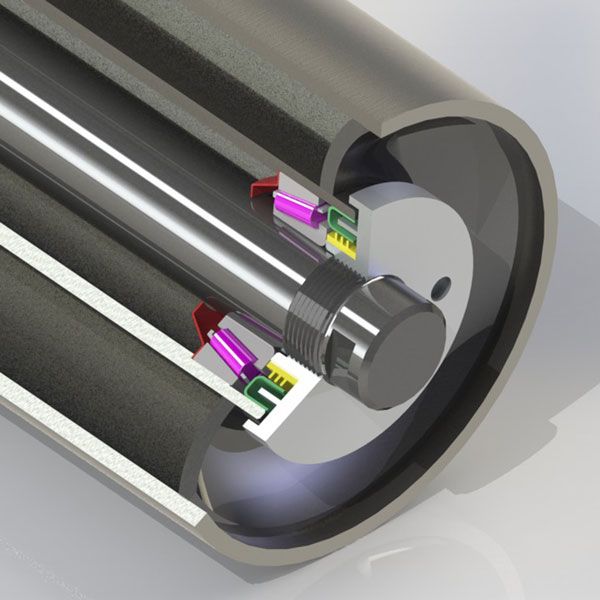

The Link-Belt F5000 idler provides extended, trouble-free service life for your belt conveyor equipment by offering oversized 1.75" bore, series 25500, precision tapered roller bearings. Bearing life of the F5000 is increased by the use of solid, cold drawn steel 1.75" diameter shafts that minimize deflection and increase load ratings. Oversized, stepped shafts are also available in 2" or 2.44" diameters to maximize idler load ratings for the most severe conveyor applications. The series F5000 idler features an exclusive, full-length center tube that is precision bored for bearing and seal seats to ensure perfect bearing/shaft alignment. The entire unit is then continuously welded robotically, ensuring an integral, airtight unit wherein contaminants and corrosion cannot enter.

Link-Belt F5000 rolls are designed for the most extreme-duty material handling applications. They feature a triple lip rubber contact seal paired with a machined steel deflector nut and integrated labyrinth seal that protect the 1.75” tapered roller bearings. F5000 rolls are available in 6”, 7”, and 8” diameters for belt widths up to 120 inches and come with standard 0.25” shell thickness. Link-Belt F5000 rolls are ideal for use on high capacity conveyors, severe impact loading areas, and high-tension areas of the return belt.