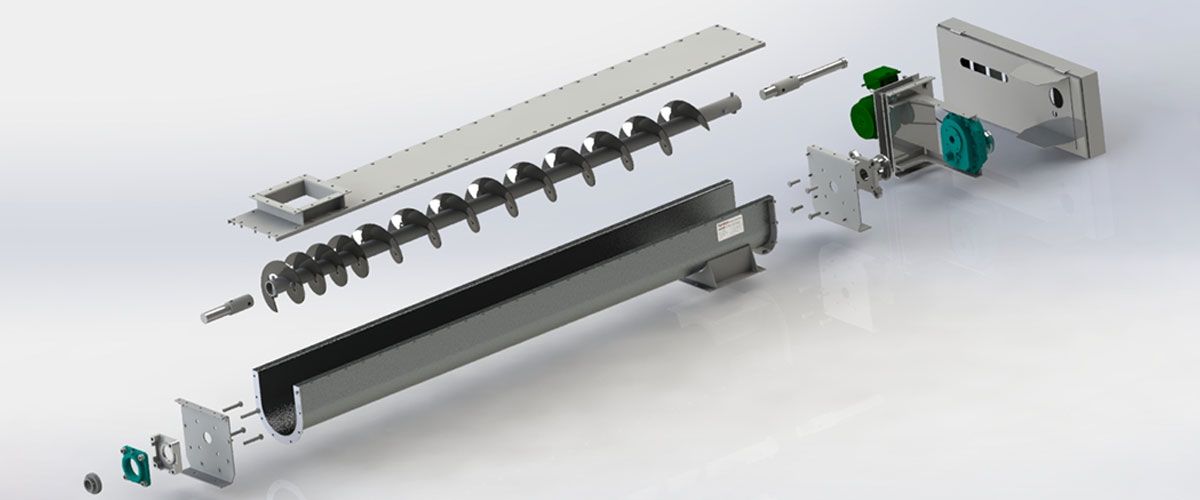

Screw Conveyor Components

Screw conveyors are one of the oldest and simplest methods for moving bulk materials and consist primarily of a conveyor screw rotating in a stationary trough. Material placed in the trough is moved along its length by rotation of the screw which is supported by hanger bearings. Inlets, outlets, gates, and other accessories control the material and its disposition.

Screw conveyors are compact, easily adapted to congested locations, and can be mounted horizontal, vertical, and in inclined configurations. Their supports are simple and easily installed.

These versatile conveyors can be used to control the flow of material in preprocessing operations which depend upon accurate batching, or as a mixer, agitator, or stirrer to mix and blend dry or fluid ingredients, provide crystallization or coagulant action, or maintain solutions in suspension.

Screw conveyors can be effectively sealed to prevent dust or fumes from escaping or dirt or moisture from entering. They can be jacketed to serve as a dryer or cooler or furnished in a wide variety of materials to resist corrosion, abrasion, or heat.

Screw conveyors are used as earth augers to dig post holes or to bore under highways for installation of culverts. They are also used extensively on combines, threshing machines, hay bailers, fodder blowers, and many other farm machines.

Screw feeders are modified screw conveyors used to control the flow of material at a constant or variable rate from track hoppers, storage hoppers, bins, or tanks. They are suitable for handling a wide variety of materials ranging from fines to a combination of fines and lumps. Under many conditions, feeders are also used as a valve.

Screw feeders are totally enclosed, compact, simple in design, and dust tight. They are economical to install, operate, and maintain.