FAQ

Frequently Asked Questions

My feeder isn’t producing an accurate feed-rate, what can I do?

Feed-rate is a function of travel speed, bed depth, and bulk density of the material. Assuming this is a newer piece of equipment, the most common culprit for inconsistent output is poor hopper design. When a feeder is installed the hopper design is critical to allow a smooth transition of material onto the pan. Also properly designing the front and rear walls allows even material flow from both the front and back of the hopper for consistent bed depth. To learn more about proper hopper design, consult our manual Working with Hoppers. This manual includes diagrams and specifications for the ideal chisel-point hopper and is located in the Knowledge Center.

Where can I find a manual for my Syntron feeder and control?

The manuals are located under the Knowledge Center.

If I purchase a new control with my Syntron feeder, is it programmed for “plug and play” ... or do I need to set the parameters after installation?

Your control is programmed with your feeder prior to shipment from the factory.

How do I set the air gap on my feeder?

You should reference your specific Syntron Service Manual for instructions. These manuals are located in the Knowledge Center.

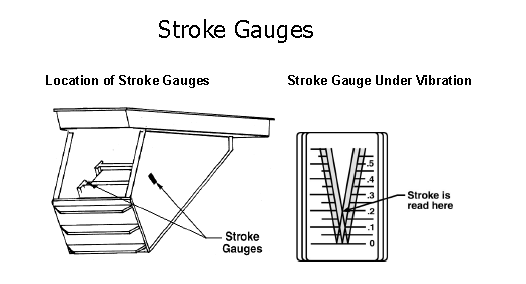

How do I read the stroke sticker on my feeder?

Can I put a larger-than-purchased trough on my feeder drive?

When changing the weight of your trough / pan, the drive will need to be re-tuned. However, if the weight of the trough exceeds maximum design limits for the original drive you will need to purchase a larger drive or consult our factory for assistance. +1 800 356 4898.

Do the vibratory feeders require a separate controller?

Yes, they run on a half-wave rectified system that requires a control to cut the sign wave in half.

Define AC and RC current?

AC = alternating current

RC = rectifying current

Can I substitute drives springs with different part numbers for Electromechanical feeders?

We do not recommend this without consulting with our engineering team first. Substitutions can be done, but only with engineering approval and instructions.

Why does the feeder just hum?

Check the Control Manual to be certain it is properly configured for your feeder and application.

What brand control is used on Syntron mechanical feeders?

Delta C2000

Why are Syntron mechanical feeders now a Direct Drive?

Fewer replacement parts—there are no bearings, seals, shafts, pulleys, or belts on our Direct Drive Mechanical feeders. The motor is all-inclusive and can be replaced from the side. See page 19 of this document: Syntron® MF Electromechanical Feeders.

Does my BF-feeder need repairing?

What are the symptoms?

What is the operational status of the control?

What is the Nameplate information from the side of the drive?

What is the age of the unit?

Is this a complete feeder (drive and trough)?

Is the control working?

The BF-2 contains a rubber spring ring.

Over the years, the rubber can become stiff and in some cases, the rubber can become un-bonded from the casting or the armature and bar assembly. At that point it is economically best to replace the drive.

If you elect to replace the drive, it is best to order it “Pre-Tuned” for the ACTUAL weight of the CURRENT trough.

Can I use Link-Belt lose rolls to replace alternate idler manufacturer’s product?

Our standard roll design might not have direct compatibility to be able to “drop it” in another manufacturer’s frame/brackets, however, we have available retrofit rolls that will serve that purpose for a wide variety of brands.

Can I use Link-Belt frames and/or brackets to replace alternate idler manufacturer’s product?

Our standard frame/brackets design will not necessarily allow direct compatibility with other manufacturers’ rolls, so we strongly recommend supplying complete Link-Belt idlers in those cases.

Do all return idlers come with brackets?

Yes, all return idlers are sold with two brackets that are figured into the price.

What is the difference in Link-Belt old style Poly rolls and your new composites?

Composites cannot be used in explosive environments.

Do the bin vibrators require a separate controller?

Yes, they run on a half-wave rectified system that requires a control to cut the sign wave in half. The V-2 and the V-4-AC can run without a control but it will not have any adjustment to the vibration.

Can we operate the rotary vibrators on a VFD (Variable Frequency Drive)?

Yes, but it still needs to be connected through an overload protected motor starter.

Where do I send inquiries and purchase orders?

Inside Sales

For standard part number (parts) inquiries and orders:

Your Inside Sales Representative will respond to this inquiry within 24 hours.

Applications Engineering

For new unit inquiries and orders

Your Applications Engineer will respond to this inquiry within 48-72 hours. We recommend using online RFQ templates to ensure all application information is complete.

Heavy Feeders and Screens:

Bucket Elevators:

Screw Conveyors:

Idlers:

Light Industry and Vibrators:

Underground Mining:

Steel Fabrication Services: