Engineered Bucket Elevators

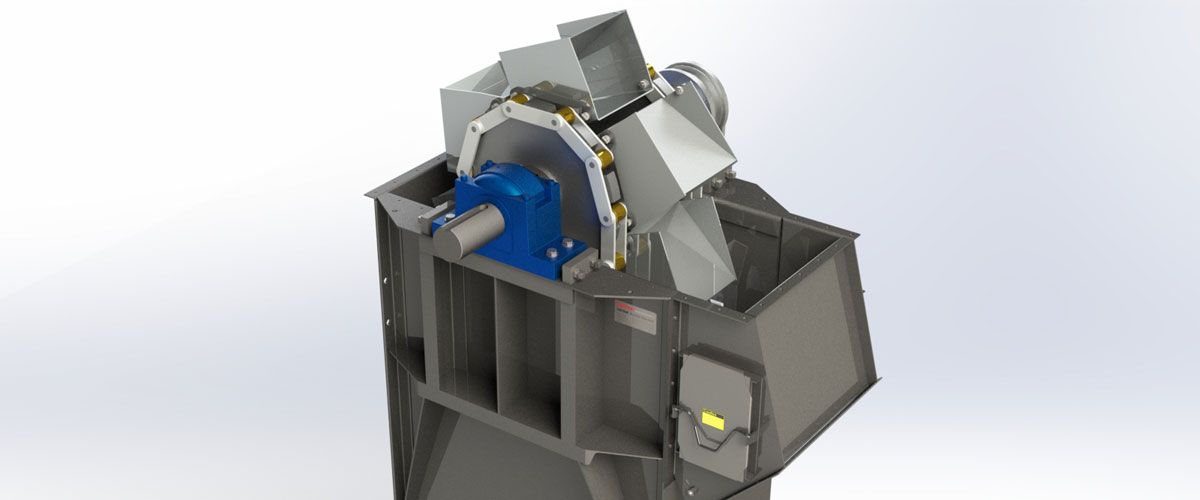

A Link-Belt® designed bucket elevator is your assurance of quality and dependability, and the standard Type 1 and Type 7 SMH bucket elevators have many outstanding features:

- Standardization of designs that are dependable and versatile.

- Continuous or centrifugal type discharge.

- Rigid, strong, jig-built casings in perfect alignment and weather-tight.

- Two-piece hood permitting access to head section interior without disturbing machinery. Spring clamps facilitate removal and replacement.

- Inspection hatch that can be easily lifted to view terminal machinery.

- Optional shaft mounted speed reducer drive- compact and easy to install.

- Large, latch-type doors located on front, back and sides of boot section to facilitate inspection, service, and cleanout.

- The head shaft is mounted in antifriction ball or roller bearing pillow blocks.

- Superior components: chains, sprockets, pulleys, belts, buckets, bearings, takeups, and drives.

Typical bulk handling applications include:

- Delivery of dry citrus pellets to railroad hopper cars.

- Elevating soda ash, fertilizer, or limestone to silo storage.

- Depositing food products into weigh hoppers.

- Lifting coal from track hoppers to storage silos.

- Elevate aggregate materials for ready-mix concrete plants.

Link-Belt® bucket elevators handle many different types of materials including:

- Metallic and non-metallic ores

- Bauxite

- Coal

- Rock products

- Sand

- Gravel

- Cement

- Gypsum

- Limestone

- Food products

- Sugar

- Flour

- Coffee

- Salt

- Chemical processing products

- Fertilizers

- Phosphates

- Agricultural lime

- Soda ash

- Pulp and paper products

- Wood chips