Cement

At Syntron Material Handling we manufacture quality Link-Belt® and Syntron® products that efficiently convey bulk materials like gypsum, limestone, stone, and gravel throughout the world. With these two legendary brands we have over 218 years of solution-driven expertise and know-how. Bring us your problem—we have a solution.

The Problem of Material Buildup due to sticky cement application

Cement Industry Solutions

Electromechanical Feeder

The Syntron vibrating feeders are designed to increase bulk handling productivity with high feed rates.

- MF - used for higher capacity requirements ranging from 600 to 4,000 tons per hour.

- HP - (smaller footprint) this new exciter optimizes design fundamentals that are crucial when providing the highest performing feeders in the industry. This feeder provides higher travel speeds and improved capacity in a more compact area.

Vibrating Screens

Syntron Material Handling vibrating screens have long been an industry leader with over 85 years of proven Link-Belt and Syntron vibrating technology experience. We offer horizontal and inclined screening technology within the aggregate, cement, chemical process, mining, industrial, and food-related industries. Our engineering and application specialists can offer an efficient and dependable solution for all your scalping, classifying, and dewatering applications.

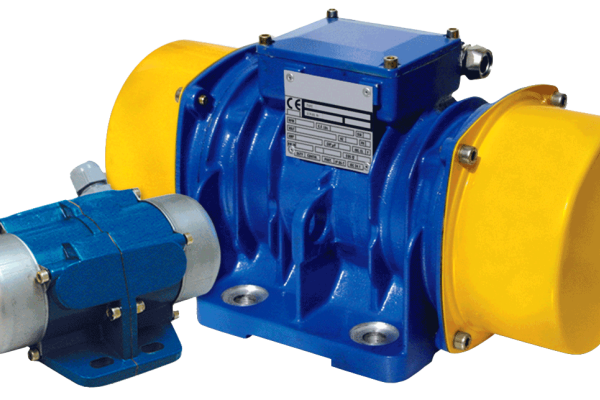

Bin Vibrator

Electromagnetic, rotary electric, or pneumatic models maintain free flow of bulk materials from bins, hoppers, and chutes. We offer effective, efficient product flow solutions for most industry applications and environments.

- Constant, uninterrupted material flow eliminates need for manual manipulation

- Trouble-free continuous operation

Link-Belt Idler

Choose from a wide range of belt conveyor idlers and parts for above-ground and underground applications.

- Meet or exceed CEMA B,C,D,E, and F series

- Retrofit availability

- Advanced sealing system

- Double sealed ball bearing designs

- Extreme service idler for oil sands applications

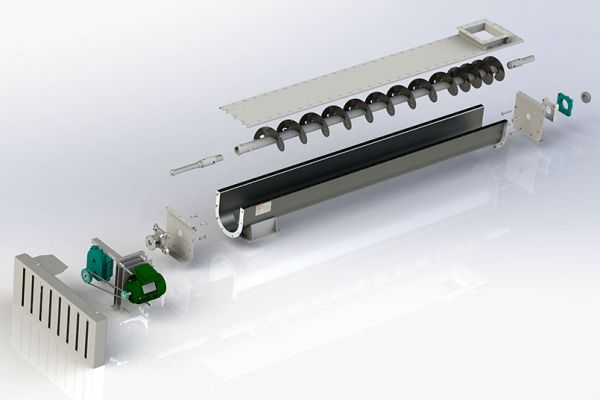

Screw Conveyor

A traditional and simple way to convey bulk materials, Link-Belt screw conveyors are perfect for:

- Batching

- Mixing

- Blending

- Agriculture

- Lawn & Garden

Bucket Elevator

A Link-Belt designed bucket elevator is your assurance of quality and dependability.

- Standardization of designs

- Continuous or centrifugal

- Rigid casings with perfect alignment / weather-tight

- Two-piece hood for easy access

- Additional components such as chains, sprockets, pulleys, etc