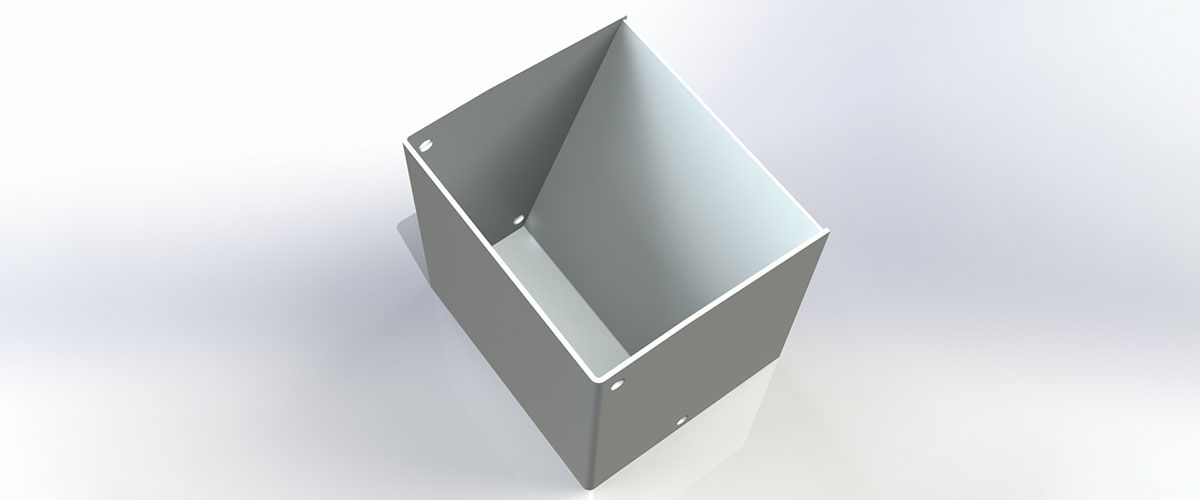

Buckets

Link-Belt elevator® buckets are designed in a variety of types and sizes to efficiently handle bulk materials in centrifugal discharge and continuous bucket elevators. Buckets are either constructed of formed steel, cast, or molded with nylon or polyethylene. Cast buckets are available in ductile iron, Promal, or ductile iron with Flint-Lip hardened digging lips.

Ductile iron is the most commonly used material in cast buckets because of its ability to withstand the effects of abrasion and stresses during digging. Promal is a pearlitic malleable with higher tensile and fatigue strength and yield point than ductile iron. Promal also has a greater resistance to abrasive wear. Ductile iron elevator buckets with Flint-Lip provide increased wear life when handling abrasive materials. Elevator buckets can also be furnished in mild steel, abrasion-resistant steel, stainless steel, and aluminum.

Type AA and MF can be supplied in either nylon or polyethylene. Centrifugal Discharge Elevator Buckets are used for handling granular, free-flowing materials which can be readily scooped up and discharged easily by centrifugal action as the buckets pass over the elevator head wheel.

When higher capacities at lower speeds are desired, or when the material being handled is friable and fragile, Continuous Elevator Buckets are used. Material is fed directly into the bucket and is discharged over the elevator head wheel onto the preceding bucket which acts as a chute, providing a clean, gentle discharge.