Ball Bearing Idlers

Link-Belt® belt conveyor idlers and components set the standard of excellence for bulk material handling throughout the world. We offer a full line of ball bearing idler products that meet or exceed CEMA B, C, D, and E specifications. Our ball bearing idlers feature advanced bearing technology for less rolling resistance than competing designs. Efficient bearing placement minimizes shaft deflection and extends bearing life. Moreover, the bearings are sealed for life, resulting in maintenance-free service. The new bearing technology also helps to ensure quality control in the manufacturing process and to extend roll life.

Link-Belt ball bearing idlers are radically different from competitive belt conveyor idlers because they incorporate an interference-fit pressed head design to maintain roll integrity. This head design eliminates welding and any of its associated problems (such as distortion, misalignment, or poor weld quality) and delivers very low total indicator runout (TIR) values compared to welded roll designs. Pressed heads, optimum bearing placement, accurate bearing alignment, and solid carbon steel shafting enable Link-Belt idler rolls to exceed CEMA load ratings.

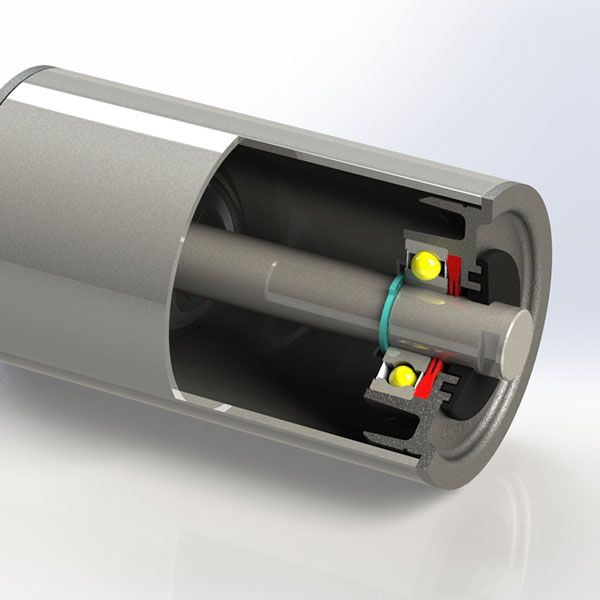

Link-Belt® CEMA B Idler

The Link-Belt CEMA B idler line features a product offering that meets CEMA B dimensional criteria and meets or exceeds CEMA B load ratings.

The Link-Belt series B2000 idler line, available in 14"-42" belt widths, is manufactured with 17 mm 6203 series, double sealed, ball bearings.

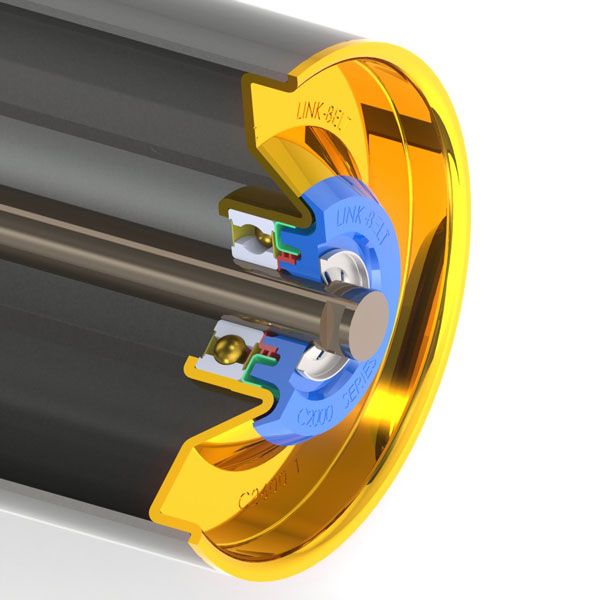

CEMA C rated C2000 Series Idler

The CEMA C rated C2000 series idler bridges the gap between the Link-Belt® series B2000 ball bearing and series C3000 roller bearing idlers by addressing the needs of less demanding applications such as sand and gravel plants. The C2000 belt conveyor idler is designed to handle a variety of light to medium weight materials. It offers a wide range of capabilities for users in pulp and paper, chemical, sand and gravel, and food processing.

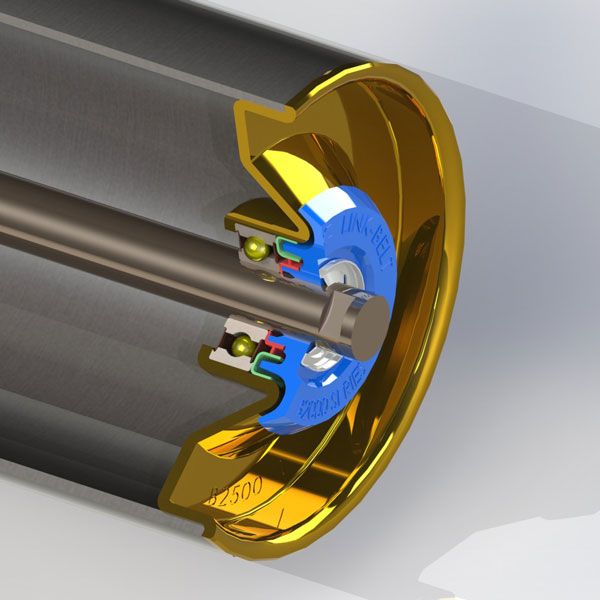

Link-Belt® D2000

Link-Belt D2000 rolls feature 30 mm ball bearings, our proprietary interference-fit pressed heads, and a quad horizontal labyrinth outer seal, a delrin outer labyrinth member, a dual lip nitrile rubber inner seal and contact seals on both sides of the bearings. D2000 rolls are designed for harsh, medium to heavy-weight applications and are available for belt widths from 18 to 72 inches, and 20°, 35° and 45° troughed belt idlers, flat return, and v-return idlers in 5" and 6" diameters.

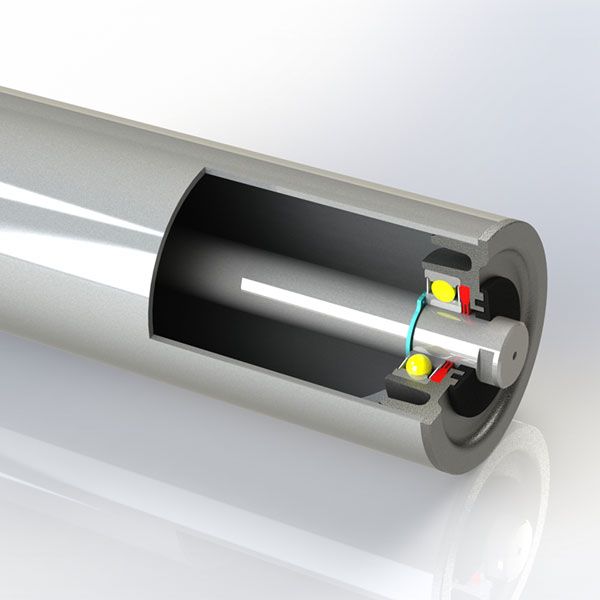

Link-Belt® E2000

Link-Belt E2000 rolls are designed for the rugged, maximum capacity and continuous handling requirements of heavy, coarse, and abrasive materials such as coal, iron ore, copper, large stone, and overburden. Featuring an exceptionally robust seal design and 40 mm ball bearings, E2000 rolls are available for belt widths from 36 to 96 inches, and 20°, 35° and 45° troughed belt idlers, flat return, and v-return idlers in 6" and 7" diameters.