Aggregates & Sand

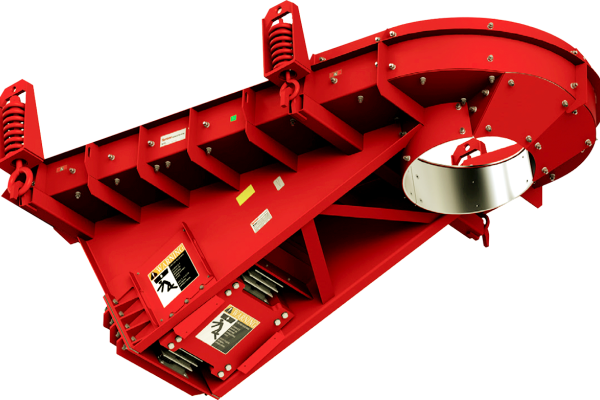

Loading Feeder

The SYNTRO-FLO Cone Crusher Loading Feeder by Syntron is a MF Two-Mass Tuned Direct Drive vibratory feeder with an engineered discharge uniquely designed for equal distribution of product.

Composite Idler Rolls

Link-Belt Idler

Choose from a wide range of Belt Conveyor Idlers and parts for above-ground and underground applications.

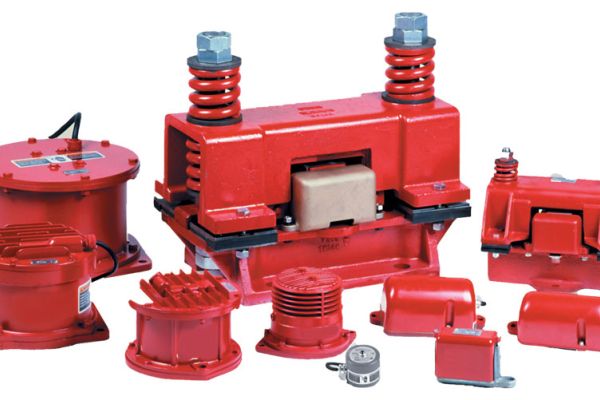

Vibrating Flow Aids

Electromagnetic, Rotary Electric or Pneumatic models maintain free flow of bulk materials from bins, hoppers and chutes. We offer effective, efficient product flow solutions for most industry applications and environments.

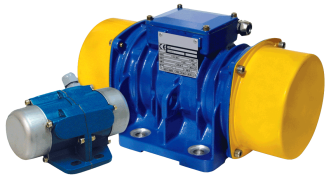

Electromechanical Feeder

The Syntron Vibrating Feeders are designed to increase bulk handling productivity with high feed rates.

Feeder Control

The Syntron Vibrating Feeders are designed to increase bulk handling productivity with high feed rates.

Electromagnetic Vibrating Feeder

With thousands of units installed over the past 80 year, Syntron Heavy-Duty Electromagnetic Feeders are the most recognized name in the industry.

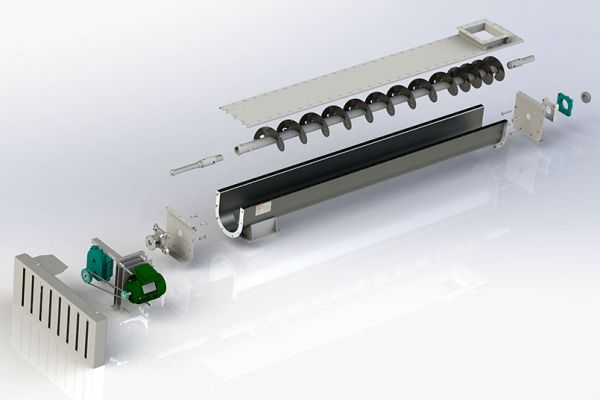

Screw Conveyor

A traditional and simple way to convey bulk materials

Vibrating Screens

Syntron Material Handling Vibrating Screens have long been an industry leader with over 85 years of proven Link-Belt and Syntron Vibrating Technology experience.

The aggregate industry is one of the largest markets we serve and our Syntron® and Link-Belt® brands are the industry standard of excellence. Our engineering expertise is legendary within sand, stone, and gravel operations across the globe.

Make sure your operation is moving material at the pace of business

Syntron Material Handling knows your business and offers solutions to all your conveying, vibrating, and screening needs. With design engineering at our core, we understand the importance of moving material from one location to the next in the most cost-effective method. We have mechanical and electrical engineers on staff to assist in your application and suggest a process to make your operation flow at maximum efficiency.

Aggregates & Sand Industry Solutions

Crusher Loading Feeder

The SYNTRO-FLO cone crusher loading feeder by Syntron is a MF two-mass tuned direct drive vibratory feeder with an engineered discharge uniquely designed for equal distribution of product. The uniform distribution delivers superior cone-friendly performance, extended life of the cone, and more cubical formed product. The feeder is suspension mounted and can be easily integrated into a trolley system allowing movement for crusher maintenance.

Link-Belt Idler

Choose from a wide range of belt conveyor idlers and parts for above-ground and underground applications.

- Meet or exceed CEMA B,C,D,E, and F series

- Retrofit availability

- Advanced sealing system

- Double sealed ball bearing designs

- Extreme service idler for oil sands applications

Composite Idler Rolls

- High corrosion resistance

- High abrasion resistance

- Excellent strength

- 50% lighter than steel rolls

Vibrating Flow Aids

Electromagnetic and rotary electric models maintain free flow of bulk materials from bins, hoppers, and chutes. We offer effective, efficient product flow solutions for most industry applications and environments.

- Constant, uninterrupted material flow eliminates need for manual manipulation

- Trouble-free continuous operation

Electromechanical Feeder

The Syntron vibrating feeders are designed to increase bulk handling productivity with high feed rates.

- MF — used for higher capacity requirements ranging from 600 to 4,000 tons per hour

- HP — (smaller footprint) this new exciter optimizes design fundamentals that are crucial when providing the highest performing feeders in the industry. This feeder provides higher travel speeds and improved capacity in a more compact area

Feeder Control

Controls by Syntron Material Handling offer a range of optional functions for specific control and requirements.

- Analog input

- Digital communication

- Onboard diagnostic capability

Electromagnetic Vibrating Feeder

With thousands of units installed over the past 80 years, Syntron heavy-duty electromagnetic feeders are one of the most recognized names in the industry. These feeders are capable of handling a variety of materials from fine powder to large, coarse particles and we offer models with ranging capacities from 25 to 1,600 tons per hour. We offer various configurations including:

- Multiple-drive units for especially long or wide pans

- Above-deck drive units (where space under the trough is insufficient)

- Below-deck drive units (standard)

Screw Conveyor

A traditional and simple way to convey bulk materials, Link-Belt screw conveyors are perfect for:

- Batching

- Mixing

- Blending

- Agriculture

- Lawn & Garden

Vibrating Screens

Syntron Material Handling vibrating screens have long been an industry leader with over 85 years of proven Link-Belt and Syntron vibrating technology experience. We offer horizontal and inclined screening technology within the aggregate, cement, chemical process, mining, industrial, and food related industries. Our engineering and application specialists can offer an efficient and dependable solution for all your scalping, classifying, and dewatering applications.